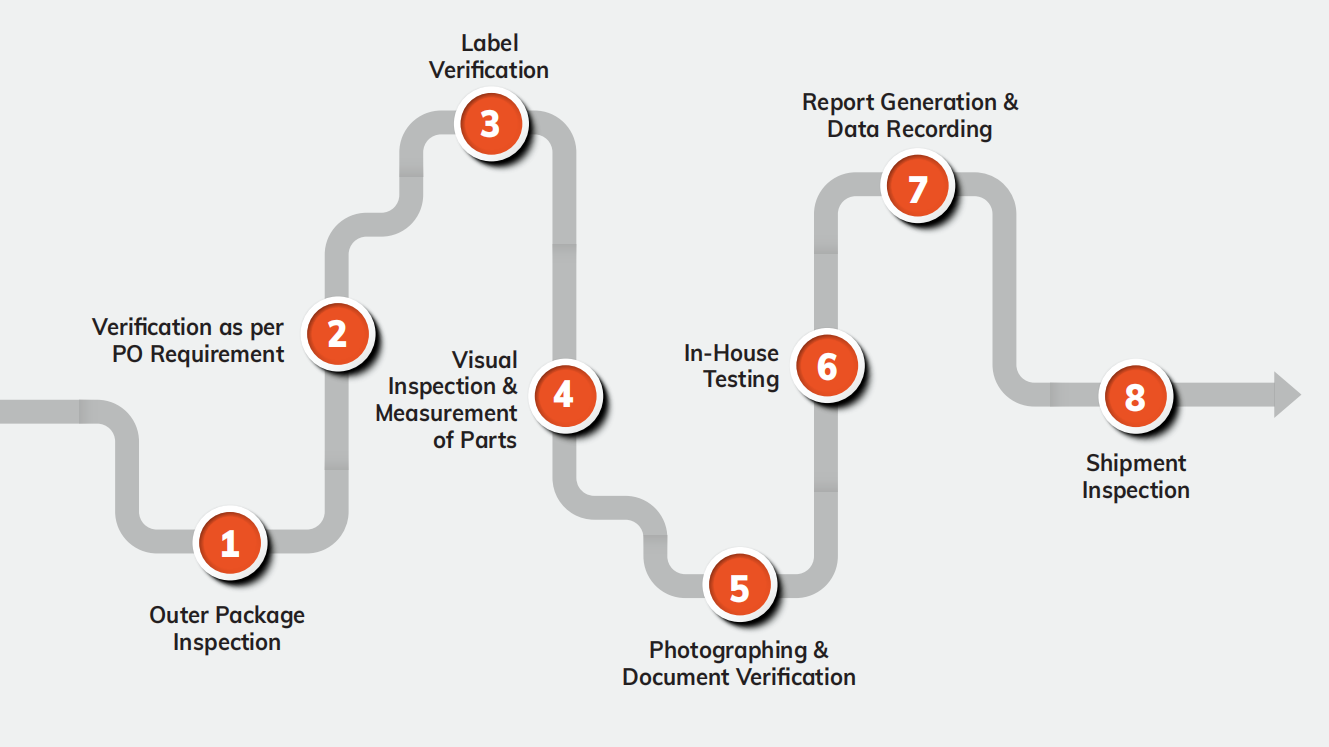

We always assure customers of delivering products of authentic quality with our comprehensive inspection & testing process!

Customer satisfaction is our ultimate goal during the course of our service. We make this happen by implementing a rigid and integrated quality management system following global standards and practices.